AllWeld 530 7 Minute Methacrylate Adhesive

AllWeld 530 7 Minute is a fast-working methacrylate adhesive formulated for adhesion to hard-to-bond materials including engineered plastics, advanced composites and exotic metals. It produces tough, flexible bonds with little or no surface preparation and cures rapidly at room temperature.

Bonds created with AllWeld 530 are load bearing and provide exceptional shear and peel strengths. They are resistant to chemicals, weather and moisture. AllWeld 530 sets to an off-white colour. As a thixotropic gel, it does not drip or run when applied to vertical surfaces.

Substrates which AllWeld 530 is compatible with include aluminium, granite, wood, UPVC, urethanes, polyesters, vinyl esters, ABS, thermoset plastics, gelcoats, GRP and epoxy laminate. It can also be used as a filler for gaps up to 4mm.

The 7-minute working time of AllWeld 530 offers long enough to accurately adjust and assemble parts before the methacrylate adhesive begins to set. It reaches handling strength in 12 minutes, reducing holding and clamping time.

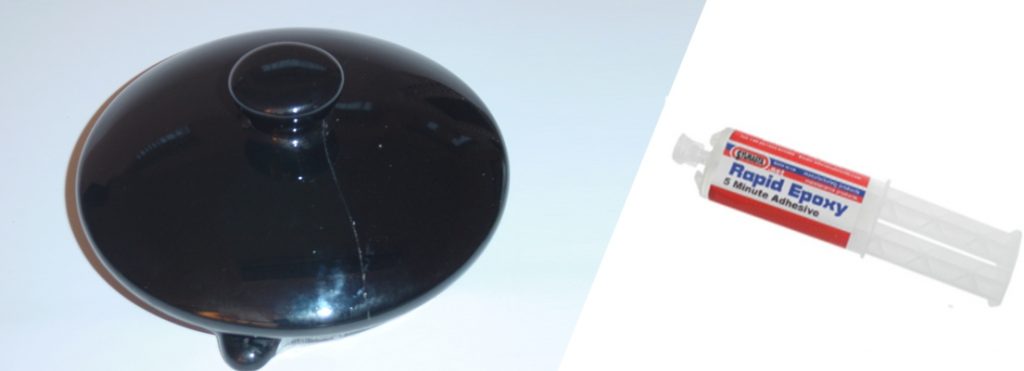

AllWeld is supplied in either a 25ml syringe or 50ml cartridge. The resin and hardener are pre-measured and extruded via a dispenser, meaning the correct 50-50 ratio is delivered for mixing.

The syringe dispenses via a plunger, whilst the cartridge requires a specialist applicator gun designed for two-part adhesives, including Sylmasta Epoxy Adhesive and UHU. Applicator guns are available to purchase separately. For more information, please contact Sylmasta.

AllWeld 530 7 Minute Methacrylate Adhesive

Because methacrylates are high-performance, specialised adhesives, always consult the safety data sheet before using for the first time.

To apply Alweld 530 from a syringe, snap off the nozzle tip and remove the cap from between the piston rods. Extrude the required amount of epoxy. With an AllWeld 530 cartridge, use the applicator gun to deliver equal amounts of methacrylate.

Once extruded, mix the two components together using a stirrer for about 30 seconds until an even mix is achieved. The mixed adhesive is applied to one of the surfaces to be repaired, after which the two surfaces requiring bonding are pressed or clamped together if required.

The working time of AllWeld530 is directly impacted by temperature, volume and substrate as it cures by exothermic reaction. Higher temperatures and larger volumes of adhesive speed the reaction.

Lower temperatures and smaller volumes slow the reaction. For more detailed information on cure times, please see the Technical Data Sheet.

At 20°C with 10g mass, AllWeld 530 has a work time of 7 minutes. Handling strength is achieved after 12 minutes. Sufficient time should be allowed for the adhesive to achieve handling strength before moving or unclamping components.

Benefits of AllWeld 530 7 Minute Methacrylate Adhesive

- Handling strength achieved in 12 minutes at room temperature

- High adhesive and impact strength

- Requires minimal surface preparation before application

- Resistant to chemicals, weather and moisture

Applications

- High strength bonding of load bearing metals, plastic, wood and composites

- Bonding difficult substrates including aluminium, stainless steel, granite, marble, UPVC, urethanes, polyesters, ABS, FRP, acrylic, GRP and gelcoats

- Bonding automotive carbon fibre body parts

- Bonding metal fasteners to moulded composite parts

- Bonding dissimilar metals for trailer fabrication

- Filling gaps up to 4mm

Technical Data

| Data | |

| Working Time | 7 minutes |

| Handling Strength | 12 minutes |

| Bond Line Thickness | 4mm |

| Colour When Set | Off-white |

Product Codes

| Code | Adhesive Quantity |

| MMA530-25ml | 25ml |

| MMA530-50ml | 50ml |

TDS Downloads

Please use the form to enquire about the price and availability of

AllWeld 530 7 Minute Methacrylate Adhesive

Related Adhesive Products

Metal Bond Rapid 5 Minute Epoxy Adhesive

Epoxy adhesive specifically formulated for use with metal, including setting dark-grey for blending. Its additional thickness enables it to be used for gap filling and its unique thrixotropic formulation means it does not drip or run when applied to vertical surfaces.

Initial Cure: 3-5 minutes

Bond Line Thickness: 4mm

Colour When Set: Dark-grey

Epoxy adhesive with a 5-minute work time and 30-minute functional cure which bonds to a range of materials including ceramic, brick, concrete, metal and most hard plastics. It sets almost transparent with bond lines under 2mm thick for a seamless repair.

Initial Cure: 3-5 minutes

Bond Line Thickness: 2mm

Colour When Set: Almost clear

CAE120 Multipurpose Cyanoacrylate Superglue

Medium viscosity cyanoacrylate superglue for general use. It forms instant bonds when sticking plastics, metal, porcelain, fine china, ceramics, jewellery and other materials, with a cure time of 3 seconds or less on non-absorbent surfaces.

Cure Time: 2–40 seconds, dependent on substrate

Viscosity: 120cps

Colour When Set: Clear