Superfast Copper Epoxy Putty Stick

Superfast Copper Epoxy Putty Stick is a copper-filled epoxy putty in an easy-to-use stick format. It has a 3-minute work time for making rapid repairs to copper, brass, bronze and other non-ferrous metals. Superfast Copper has WRAS approval and is most commonly used in pipe repair applications.

Each Copper Stick weighs 114g, has a nominal 22mm diameter and is 175mm long. It contains resin on the outside and hardener in the middle. The user simply cuts off the required amount of putty from the Stick and kneads by hand before applying to the substrate to be repaired or bonded.

Superfast Copper is pushed into cracks and holes in copper pipework when pressure is turned off. It will quickly cure to a rock-hard material, sealing the leak with pressure resistance to 30 bar. WRAS approval means Superfast Copper is certified as safe to use with drinking water.

Away from pipe repair, Superfast Copper fills holes and bonds parts together. It is used in restoration projects and for repairing damaged statues. It is easy to work and mould for artists and sculptors making copper-coloured figurines.

Although the target substrates are copper and other non-ferrous metals, it adheres to most other materials. It sets to a bronze colour to appear uniform with copper.

Superfast Copper is resistant to water, chemicals and temperatures up to 150ºC. It makes interior or exterior repairs. Within one hour of application, systems can be put back into full use. The cured material can be tapped, drilled, screwed, sawed, machined, ground, filed, or painted.

Superfast Copper Epoxy Putty Stick Details

To use a Superfast Copper Stick, the amount of epoxy putty required is cut off and kneaded by hand until it turns a uniform bronze colour with no streaks.

Whilst soft, the putty is pushed into holes and cracks in pipes and metalwork where it will cure, sealing and filling areas of damage. For bonding, you apply the putty and use it to attach the pieces requiring repair together.

Superfast Copper has a work life of approximately 3 minutes. Within 5–10 minutes, it will harden and form a cohesive bond. A full repair is completed in one hour.

It contains no solvents or VOC’s, it is non-flammable and releases no noxious fumes. It will not shrink or pull away and the unused portion of Copper Stick stays fresh for future use when saved in its original package.

Pipe repairs made with Superfast Copper Stick can be overwrapped with a SylWrap Pipe Repair Bandage for added reinforcement.

SylWrap Bandage can be purchased along with Superfast Steel Epoxy Putty as part of the SylWrap Standard Pipe Repair Kit. The Standard Kit fixes leaking pipes of most materials, including copper.

Please note that Superfast Copper is only effective for fixing a leaking copper pipe where water pressure can be turned off. For carrying out live leak pipe repairs, please see Wrap & Seal Waterproof Pipe Burst Tape.

For repairs subjected to extreme heat in excess of 150°C, please see Superfast Titanium High Temperature Epoxy Putty Stick. Superfast Titanium has been specifically formulated to offer temperature resistance up to 280°C.

Benefits of Superfast Copper Epoxy Putty Stick

- Copper-filled and specifically designed for use with copper and similar metals

- Easy to use – simply cut off the putty, knead by hand and apply

- Repairs can be made in less than 15 minutes

Applications

- Copper repair, brass repair, bronze repair, non-ferrous metal repair

- Sealing leaks in copper pipes

- High-strength bonding

- Interior or exterior repairs in domestic plumbing and industrial settings

- WRAS approved for use on pipes carrying drinking water

Technical Data

| Data | |

| Work Time | 3 minutes |

| Functional Cure | 1 hour |

| Full Cure | 24 hours |

| Max Service Temp | 150°C |

Product Codes

| Code | Putty Quantity |

| SFCOP-114g | 114g |

TDS Downloads

Superfast Copper Epoxy Putty Stick Case Studies

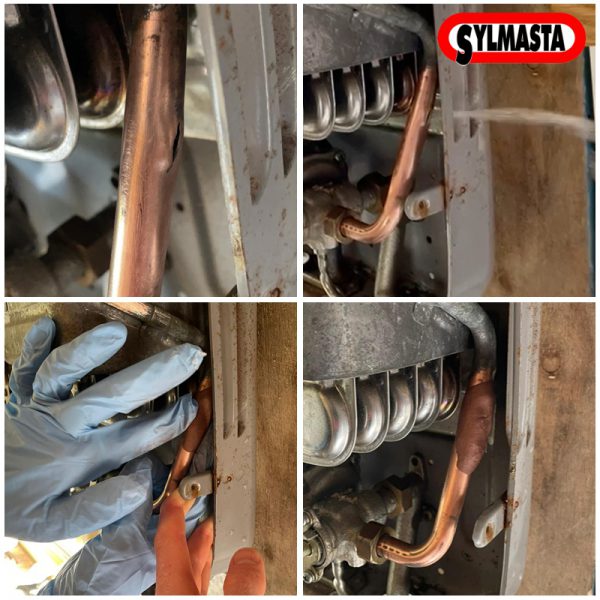

Case Study: Burst Copper Pipe Repair in Portable Horse & Dog Shower Unit

Case Study: Oil Refinery Repair of a Leaking Underground GRP Seawater Return Pipe

Case Study: Repair of a Cracked Copper Pipe in a Camper Van Boiler System

Case Study: Buried 600mm Asbestos Cement Pipe Leaking Sleeve Repair in Mexico

Case Study: Argentina Oil Well 900mm Steel Pipe Surface Restoration & Repair

Case Study: Leak Repair of a Pierced 300mm Plastic Pipe in a Quarry Wash Plant

Superfast Copper Epoxy Putty Stick Videos

No pressure repair of a leaking steel pipe

Superfast Copper Epoxy Putty Stick being used as part of the SylWrap Standard Pipe Repair Kit to carry out a repair to a 95mm steel pipe at Sylmasta HQ.

Please use the form to enquire about the price and availability of

Superfast Copper Epoxy Putty Stick

Related Pipe Repair Products

WRAS approved pipe repair tape made from self-amalgamating silicone. It stretches by three times its length, fusing to form a solid rubber band around pipework capable of sealing live leaks.

Live Leaks: Yes

Number of Repairs: One

Pressure Resistance: Up to 30 bar

Temperature Resistance: Up to 200ºC

SylWrap Standard Pipe Repair Kit

The Standard Pipe Repair Kit contains Superfast Epoxy Putty and SylWrap Bandage. It makes a single, WRAS approved, permanent repair to a leaking pipe where pressure can be turned off.

Live Leaks: No

Number of Repairs: One

Pressure Resistance: Up to 30 bar

Temperature Resistance: Up to 120ºC

SylWrap Universal Pipe Repair Kit

The Universal Pipe Repair Kit contains Superfast Epoxy Putty, Wrap & Seal and SylWrap Bandage. It makes a single, WRAS approved, permanent repair to live leaks where pressure cannot be turned off.

Live Leaks: Yes

Number of Repairs: One

Pressure Resistance: Up to 30 bar

Temperature Resistance: Up to 120ºC