Case Study: Repair of a Cracked Copper Pipe in a Camper Van Boiler System

Carry on camping – a camper van owner fixes a difficult-to-access crack in their boiler

A camper van owner manages to repair a crack in a copper pipe located within the van’s boiler system, despite the leak area being extremely difficult to access.

Case Study Data

Site

Camper van boiler

Location

United Kingdom

Repair Type

Leak repair

Defect

Crack in a copper pipe

Products Used

Superfast Copper Epoxy Putty Stick

Fast-working epoxy putty pushed into the crack in the copper pipe to seal it

SylWrap HD Pipe Repair Bandage

Composite repair wrap applied over Superfast Copper to reinforce the initial repair

SylWrap Standard Pipe Repair Kit

Superfast Epoxy and SylWrap HD are supplied together in the Standard Pipe Repair Kit

Case Study PDF

Case Study Details

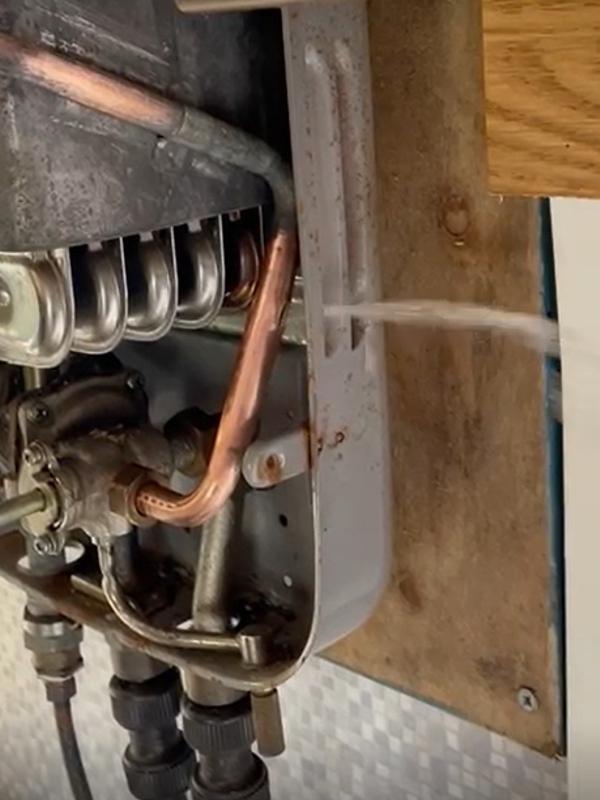

The boiler system provided heat and hot water to the camper van. A deep crack appeared in a copper pipe located underneath the cover of the boiler, causing a pressurised jet of water to spray out whenever the boiler was turned on.

Problematically, the crack was located at a point where the pipe angled towards the back casing of the boiler. It faced towards the side of the casing with access extremely limited.

The confined space meant that there was no room to fit a pipe repair clamp, nor apply Wrap & Seal Pipe Burst Tape with enough stretch for it to self-amalgamate effectively.

Because the boiler could be turned off, Sylmasta recommended to the camper van owner that they use Superfast Copper Epoxy Putty Stick to plug the crack in the pipe.

Superfast Copper comes in a 114 gram stick format and has a work time of 5 to 10 minutes, enabling rapid repairs to be made to copper and other non-ferrous metals.

Before the application began, the pipe was cleaned and dried to aid the adhesion of the putty to the metalwork. The required amount of putty was cut from the stick and kneaded by hand.

Whilst soft, the putty was pushed into the crack in the copper pipe where it hardened, sealing the hole. Enough putty was used to cover the section of pipe both above and below the crack to improve the chances of success.

To reinforce the putty, the entire section of pipe was then covered with a SylWrap HD Pipe Repair Bandage. SylWrap HD is a composite repair wrap with a water activated resin which sets rock hard in minutes to provide an impact resistant layer of protection.

Typically, SylWrap HD would be wrapped around the pipe. The space constraints meant that this could not be done effectively in this particular application, and so the bandage was cable tied to the pipe whilst it cured.

Once the copper pipe repair was completed, the boiler was turned back on. Water was no longer escaping from the crack, denoting a successful boiler pipe repair and saving a considerable amount of money for the camper van owner compared to the cost of fitting a replacement pipe.

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com