Case Study: Creating a Flexible Expansion Joint Filler for a Residential Property in the UK

Sealing the Dream – Sylmasta Liquid Rubber used as a flexible expansion joint filler eliminates problematic balcony drips at a dream home

Liquid Rubber solves an unexpected issue at a dream home being built in Essex when used as a filler to prevent water dripping from the roof terrace through the gap for glass panel expansion and onto the balcony below.

Case Study Data

Site

Residential Property

Location

Essex, United Kingdom

Repair Type

Expansion Joint Filler

Defect

Water dripping through expansion gaps in a roof terrace onto a balcony below

Products Used

Liquid Rubber 80

Rubber elastomer compound which was poured into the expansion joints to offer a water resistant and flexible filler

Case Study PDF

Case Study Review

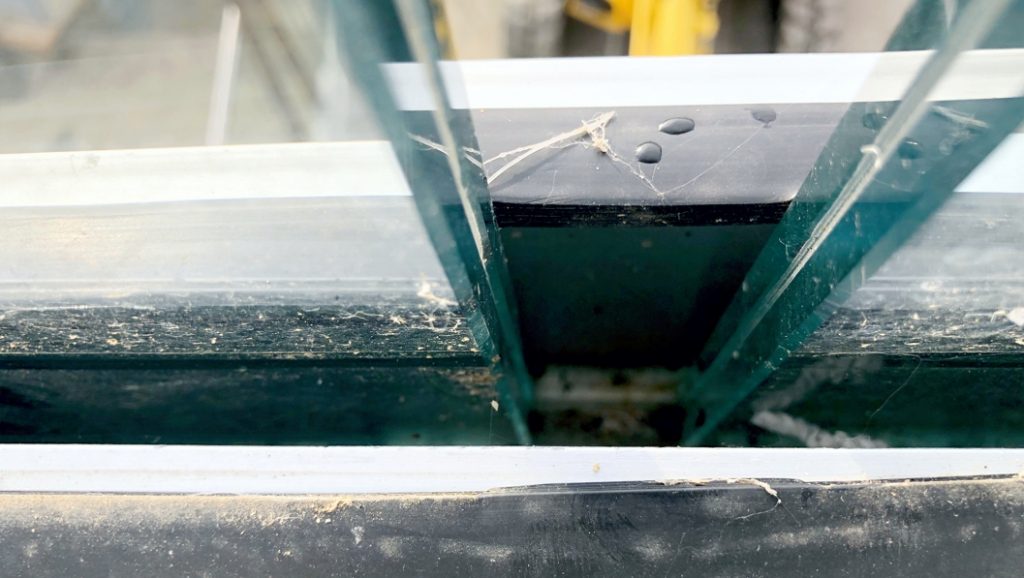

The striking property overlooking the Thames Estuary featured a roof terrace with panoramic views. Surrounding the terrace were 26 glass panels with 25mm expansion gaps either side. Below the roof terrace was another balcony where electrical installations such as LED lights and speakers had been added.

Whenever it rained or spray blew in off the Thames, water would drip through the expansion gaps and onto the balcony below, causing issues with the electric equipment.

To prevent this happening, the homeowner needed to find an expansion joint filler material which was both waterproof to eliminate the drips and flexible enough to allow the glass panels to expand. After speaking with Sylmasta, the homeowner decided to use Liquid Rubber 80 as an expansion gap filler in conjunction with a packing material.

Liquid Rubber is a tough but flexible repair compound which can also be used to refurbish conveyor belts, make moulds, and add noise-reducing and abrasion-resistant linings to equipment.

The packing material was first pushed into the expansion gaps. Once the material was in place, the homeowner mixed the two parts of Liquid Rubber together, pouring it into the joints to seal everything.

Within 16 hours, the Liquid Rubber cured to provide a water resistant filler which could also cater for glass expansion.

Liquid Rubber sets to black, which meant that it blended in seamlessly with the resin which had been used on the rest of the roof terrace’s balustrade. Even on close inspection, you could not tell that two different materials had been used.

The use of Liquid Rubber as an expansion joint filler was a complete success and eliminated all drips from the roof terrace to the balcony below.

The homeowner contacted Sylmasta after the repair had been completed, saying he was delighted that a solution had been found to complete the building work on his dream home.

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com