Case Study: High Temperature Live Leak Pipe Repair in an on-site CHP Plant

Saving the planet, one Plant at a time – Sylmasta keep a carbon-reducing Combined Heat & Power Plant operational

A leaking pipe in the CHP Plant of an automotive safety supplier’s factory could have caused serious issues to the site’s power supply and energy efficiency until Sylmasta provided a high temperature repair method

Case Study Data

Site

Automotive Safety Supplier Factory

Location

West Midlands, United Kingdom

Repair Type

Live leak pipe repair

Defect

Leaking elbow in a high temperature pipe

Products Used

SylWrap Universal Pipe Repair Kit

A Universal Pipe Repair Kit was sent to the factory for the repair

Wrap & Seal Pipe Burst Tape

Wrap & Seal provided the required temperature resistance and versatility to seal a leaking elbow joint

SylWrap HD Pipe Repair Bandage

The entire repair was overwrapped with SylWrap HD for an impact resistant layer of protection

Case Study PDF

Case Study Review

Combined Heat and Power (CHP) Plants are used to increase energy efficiency and drive down costs at industrial sites. CHP captures the heat produced when electricity is generated that would otherwise be wasted, using it to provide thermal energy such as steam or hot water. This can then be used for the heating or cooling of sites, producing domestic hot water, or industrial processes.

Typically, a CHP Plant can reduce a site’s energy bills by 20% and carbon emissions by 30% – as long as the system is in good working order. When the systems in a CHP Plant develop a fault or are not managed correctly, then these savings are lost.

Depending on how reliant the site is on the heat supplied by CHP, faults can also be extremely disruptive – especially if the Plant has to be taken completely out of service to have parts replaced.

It looked like this was a problem that an automotive safety supplier in the United Kingdom was going to face when a pipe in their factory’s CHP Plant began leaking. Although it was not a major leak, water was dripping onto other components in the CHP system, including motors and gas tanks which were stored underneath the damaged pipe.

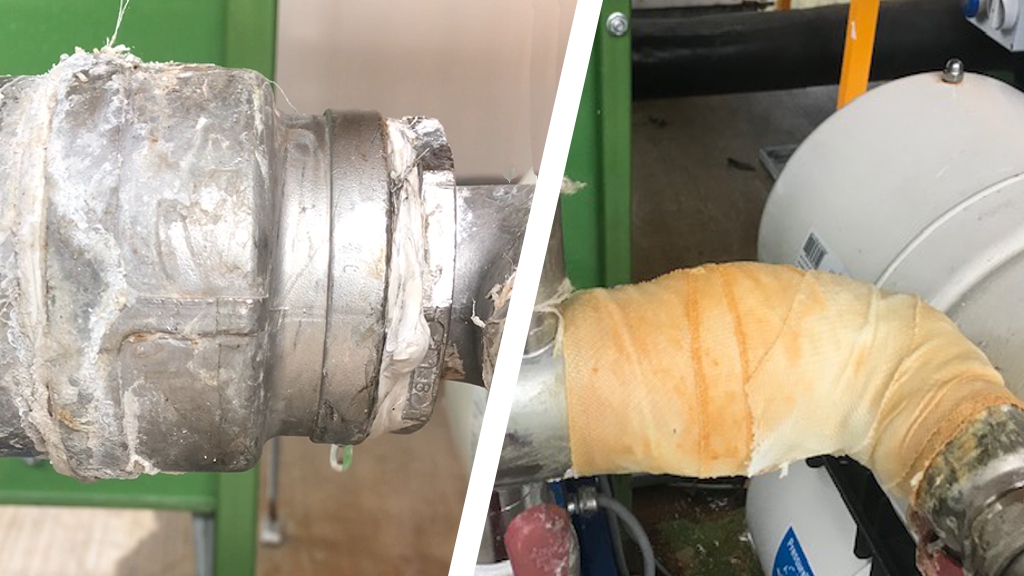

There were three issues which made the repair challenging. The first was that the leak was on an elbow joint, making it difficult to form a tight seal around the damaged area in order to repair it.

The second was that CHP systems deal with extreme temperatures. The pipe requiring repair operated in excess of 120°C, so a solution that was effective in high temperature applications was required.

The third was that the automotive safety supplier could only take the CHP Plant out of service as a last resort. This meant that a live leak repair needed to be carried out to avoid considerable disruption.

After contacting Sylmasta to discuss whether a successful live leak repair on a high temperature elbow joint was possible, a SylWrap Universal Pipe Repair Kit was delivered to the site, enabling the staff at the factory to complete the repair themselves.

Wrap & Seal Pipe Burst Tape was applied around the leaking elbow joint. The waterproof repair tape was stretched to the maximum 300% of its length and wrapped around the pipe, where it fused into a silicone band to seal the leak.

The initial repair was then overwrapped with a SylWrap HD Pipe Repair Bandage, which is water-activated and sets rock-hard in minutes to form a protective layer, ensuring a permanent repair to the pipe.

Both Wrap & Seal and SylWrap HD Pipe Repair Bandage are resistant up to 200°C, making them suitable for use on high temperature pipework such as those in a CHP Plant. The Bandage did cure with a red tinge because of the temperature extremes. Should the automotive safety supplier want the repair to appear more uniform with the rest of the pipe in the future, then SylWrap HD can be painted.

After the CHP Plant repair had been completed, the automotive safety supplier got in contact with Sylmasta to say that they were extremely impressed with the ease and speed which with which they had been able to carry out the repair.

For dealing with future leaks, not just in their CHP Plant but across the whole site, Sylmasta recommended that the company take stock of a SylWrap Pipe Repair Contractor Case. The Case contains enough products to make up to six pipe repairs. Keeping one on-site would enable the automotive safety supplier to quickly repair leaking pipes as soon as problems arise.

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com