Superfast Steel Epoxy Putty Stick

Superfast Steel Epoxy Putty Stick is a steel-filled epoxy putty in an easy-to-use stick format. It has a 3-minute work time for making rapid repairs to steel, iron and other ferrous metals. Superfast Steel has WRAS approval and is most commonly used in pipe repair applications.

Each Steel Stick weighs 114g, has a nominal 22mm diameter and is 175mm long. It contains resin on the outside and hardener in the middle. The user simply cuts off the required amount of putty from the Stick and kneads by hand before applying to the substrate to be repaired or bonded.

Superfast Steel is pushed into cracks and holes in domestic and industrial pipework when pressure is turned off. It will quickly cure to a rock-hard material, sealing the leak with pressure resistance to 30 bar. WRAS approval means Superfast Steel is certified as safe to use with drinking water.

It also repairs exterior pipe surface damage caused by pitting and corrosion. Applying Superfast Steel to fill-in and rebuild weakened areas increases outer wall thickness, strengthening pipeline integrity.

Away from pipe repair, Superfast Steel fills holes in metal machinery and bonds parts together. Although the target substrate is steel, it adheres to most other materials. It sets to a grey colour to appear uniform with metalwork.

Superfast Steel is resistant to water, chemicals and temperatures up to 150ºC. It makes interior or exterior repairs. Within one hour of application, systems can be put back into full use. The cured material can be tapped, drilled, screwed, sawed, machined, ground, filed, or painted.

Superfast Steel Epoxy Putty Stick Details

To use a Superfast Steel Stick, the amount of epoxy putty required is cut off and kneaded by hand until it turns a uniform grey colour with no streaks.

Whilst soft, the putty is pushed into holes and cracks in pipes and metalwork where it will cure, sealing and filling areas of damage. For bonding, you apply the putty and use it to attach the pieces requiring repair together.

Superfast Steel has a work life of approximately 3 minutes. Within 5–10 minutes, it will harden and form a cohesive bond. A full repair is completed in one hour.

It contains no solvents or VOC’s, it is non-flammable and releases no noxious fumes. It will not shrink or pull away and the unused portion of Steel Stick stays fresh for future use when saved in its original package.

Pipe repairs made with Superfast Steel Stick can be overwrapped with a SylWrap Pipe Repair Bandage for added reinforcement. Superfast Steel and SylWrap Bandage can be purchased together as part of the SylWrap Standard Pipe Repair Kit.

Please note that for fixing a steel or iron pipe, Superfast Steel is only effective when water pressure can be turned off. For carrying out live leak pipe repairs, please see Wrap & Seal Waterproof Pipe Repair Tape.

For repairs subjected to extreme heat in excess of 150°C, please see Superfast Titanium High Temperature Epoxy Putty Stick. Superfast Titanium has been specifically formulated to offer temperature resistance up to 280°C.

Benefits of Superfast Steel Epoxy Putty Stick

- Specifically designed for use with steel, iron and similar metals

- Does not rust

- Easy to use – simply cut off the putty, knead by hand and apply

- Repairs can be carried out in under 15 minutes

Applications

- Steel repair, iron repair, other ferrous metals repair

- Large domestic pipe repair and industrial pipe repair

- Repair of small areas of damage caused by corrosion to restore surface profile

- Suitable for interior or exterior use

- Bonds steel with other metals, wood, glass, masonry, and many plastics

- WRAS approved for use on pipes carrying drinking water

Technical Data

| Data | |

| Work Time | 3 minutes |

| Functional Cure | 1 hour |

| Full Cure | 24 hours |

| Max Service Temp | 150°C |

Product Codes

| Code | Putty Quantity |

| SFST-114g | 114g |

TDS Downloads

Superfast Steel Epoxy Putty Stick Case Studies

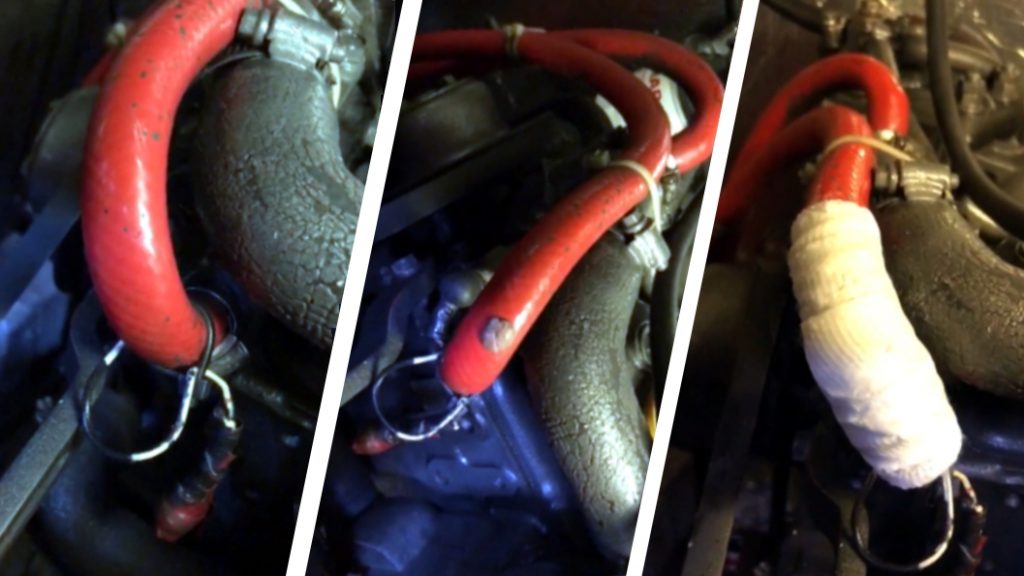

Case Study: Boat Owner Repairs Pinhole Leak in Rubber Hose Connected to Engine

Case Study: External Surface Damage Repair to Restore Integrity of 400mm GRP Pipe

Case Study: Leaking Hydrogen Line Pipe Repair at Power Station in Puerto Rico

Case Study: Superfast Steel Epoxy Putty Used to Fix Rust Holes on a Classic Car

Case Study: Repair of a Leaking 150mm Steel 90 Degree Elbow Bend at a Quarry Wash Plant

Case Study: Repair of a Cracked 90-year-old 70mm Malleable Iron Water Supply Pipe

Case Study: ‘Impossible’ Repair of a 900mm Water Main Flange Leak in an Underground Chamber

Case Study: Magic Corner Kitchen Unit Repair Saves a Client Over £200 in Replacement Costs

Case Study: 19th Century Lantern Restoration Using Superfast Steel Epoxy Putty

Case Study: Emergency Repair of Hospital 300mm Air Conditioning Pipe on Hottest Day of June

Case Study: Repair and Reconnection of a Ruptured 20bar Cast Iron Water Supply Pipe

Case Study: Leaking Cast Iron Wastewater Pipe Repair at a London Hotel

Case Study: Pinhole Repair of a Steel Pipe in a Furniture Factory Sprinkler System

Superfast Steel Epoxy Putty Sticks Videos

Repair of a corroded leaking pipe made using Superfast Steel

Test repair carried out in the Sylmasta Lab using Superfast Steel to seal a leak on a corroded steel pipe.

Please use the form to enquire about the price and availability of

Superfast Steel Epoxy Putty Stick

Related Metal Repair Products

Industrial Metal Epoxy Repair Paste

Metal-filled epoxy paste which rebuilds worn parts, fills cracks and protects against corrosion and chemical attack. It is the only Sylmasta epoxy paste which cures on wet surfaces and is BS 6920 compliant when used with SylWrap Bandage in pipe repair applications.

Work Time: 60 minutes

Functional Cure: 90+ minutes

Max Service Temp: 130ºC

Titanium Supergrade HT Epoxy Paste

Alloy-filled epoxy paste with very high compressive strength and extreme temperature resistance. It is used for the repair and maintenance of systems operating in environments up to 250ºC and stress-bearing equipment including shafts, keyways and splines.

Work Time: 180 minutes

Functional Cure: 16 hours

Max Service Temp: 250ºC

Versatile, metal-filled coating with a wide range of repair, refurbishment and maintenance uses. It offers excellent protection against corrosion and chemical attack, curing to form a protective outer shield around pipework, equipment, machine parts and surfaces.

Work Time: 90 minutes

Re-coat Time: 4-8 hours

Max Service Temp: 150ºC