Sylmasta Case Studies

Sylmasta supply pipe repair and maintenance solutions for infrastructure operators, utility suppliers, multinational corporations and government departments as well as small businesses and individuals worldwide – the case studies section of this website showcases some of the projects that Sylmasta have been involved in.

If you have any questions about any of the solutions supplied by Sylmasta or require help with an application of your own, then please contact us and a technician will be happy to assist you.

Case Study: Magic Corner Kitchen Unit Repair Saves a Client Over £200 in Replacement Costs

The high-strength bonding properties of Superfast Steel Epoxy Putty Stick repair a damaged magic corner kitchen unit which would have cost £290 to replace

Case Study: 19th Century Lantern Restoration Using Superfast Steel Epoxy Putty

Superfast Steel Epoxy Putty is used in the restoration of a Victorian candle-lit lantern dated to the 1870s or 1880s, returning the item to full working order

Case Study: Snapped Nozzle on a 1500mm Seawater Cooling Line Repair & Reinforcement

The main supply line in a seawater cooling system undergoes urgent repair and reinforcement after a snapped nozzle began discharging water 5 metres into the air

Case Study: Live Leak Pinhole Repair on 150mm Elbow at Pumping House in Malaysia

An elbow joint leaking from a pinhole in a Malaysia pumping house undergoes a live leak repair under 6 bar pressure which enabled systems to remain operational

Case Study: Repair of a Leaking 200mm Fuel Oil Line Pressure Resistant to 44 bar in Libya

A corroded underground 200mm fuel oil in Libya leaking through a small crack is sealed with a repair pressure resistant to 44 bar and capable of withstanding temperatures of up to 70°C

Case Study: Repair of a Cracked Copper Pipe in a Camper Van Boiler System

A camper van owner repairs a very difficult-to-access copper pipe in the van’s boiler system which was leaking water through a large crack whenever the boiler was turned on

Case Study: Bahrain International Airport Repair of Leaking Step Joint on 100mm UPVC Pipe

Systems are kept operational at Bahrain International Airport thanks to an under pressure repair on a 100mm UPVC pipe leaking from a step joint

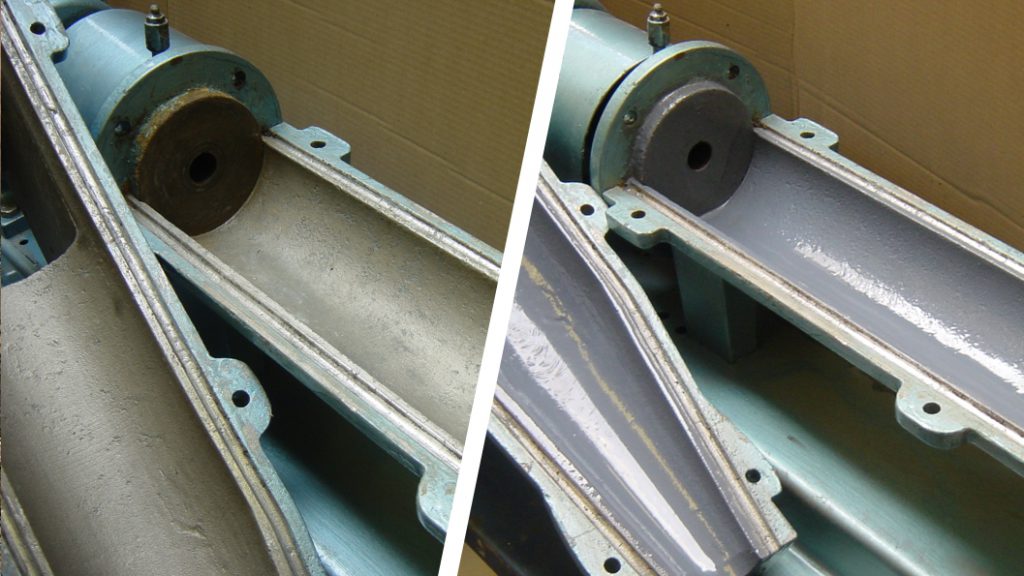

Case Study: Creating an Abrasion Resistant Surface for Pug Mill Extruder Barrels

Ceramic Brushable Blue is used to coat pug mill putty extruder barrels, creating an abrasion resistant surface to increase extrusion efficiency and protect against future wear

Case Study: Repair & Refurbishment of a 19th Century Pit Wheel at Mordiford Mill

Sylmasta AB provides a waterproof, corrosion resistant material to protect a 19th century pit wheel from water ingress and help bond two steel hoops to its castings for reinforcement

Case Study: Reinforcement of Weakened Pipe Elbow Joint on 100mm 22 bar Sulphuric Acid Line

An elbow on a 100mm sulphuric acid pipeline which had degraded from 22mm thickness to just 1mm undergoes urgent reinforcement in a petrochemical refinery in Saudi Arabia

Case Study: 650mm Ductile Iron Pipe Located in Pit Undergoes Live Leak Coupling Joint Repair

Coupling joints connecting a 2 metre long section of 650mm ductile iron pipe with a water line buried in an old inspection pit are sealed after they were discovered to be leaking

Case Study: Live Leak Repair of a Cracked 4 bar 250mm PCCP Pipe Stub in Saudi Arabia

After several failed repair attempts, a cracked 250mm PCCP stub under 4 bar pressure with no isolation valve in Saudi Arabia undergoes a live leak repair followed by reinforcement

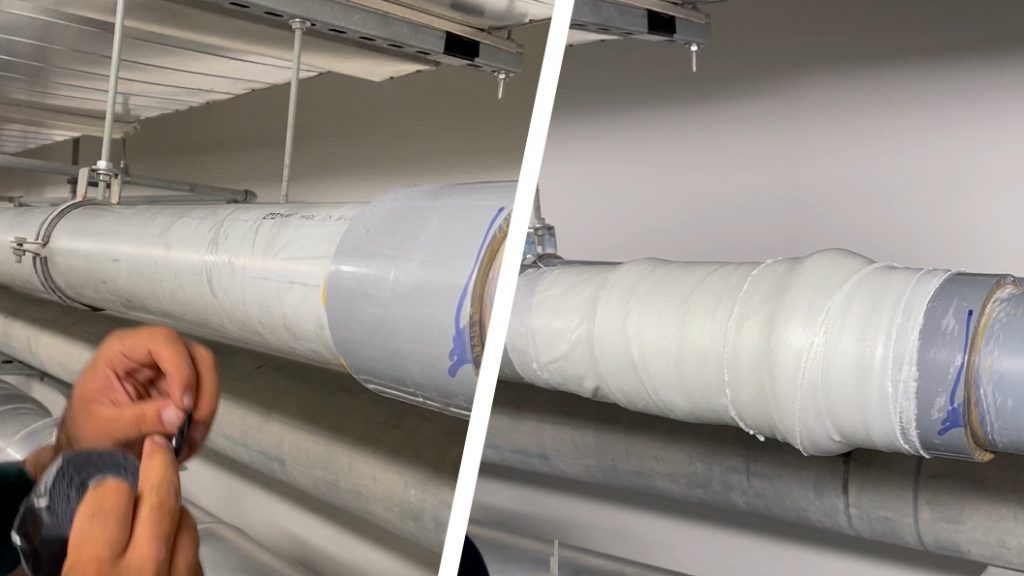

Case Study: Emergency Repair of Hospital 300mm Air Conditioning Pipe on Hottest Day of June

On a day when temperatures in London hit 27ºC, a burst 300mm pipe forced the shutdown of a hospital air conditioning system until a SylWrap repair was made

Case Study: Buried 600mm Asbestos Cement Pipe Leaking Sleeve Repair in Mexico

Leaks at both ends of a sleeve on a buried 600mm asbestos cement pipe are permanently sealed to prevent any more fluid escaping by a water utility company in Mexico

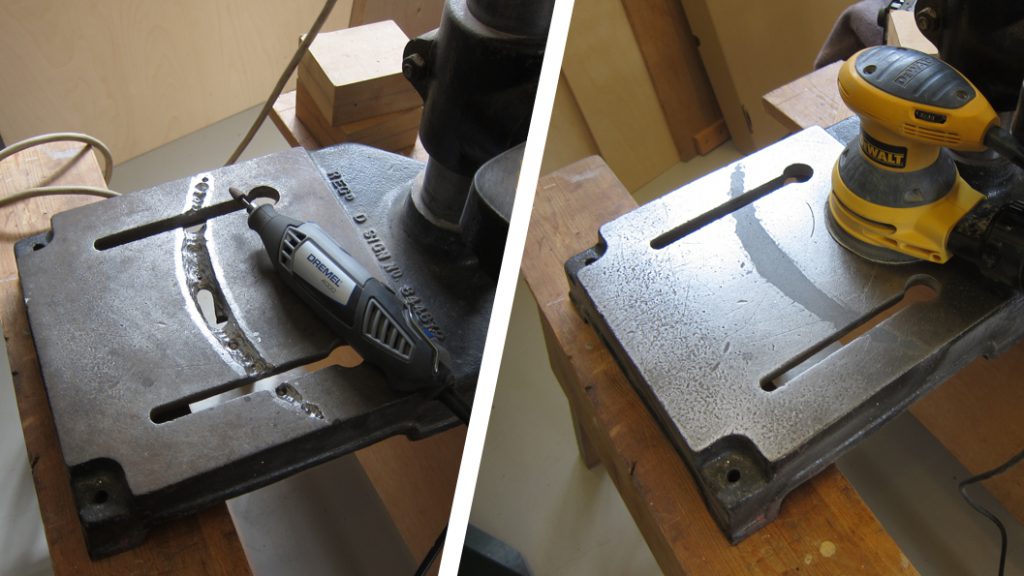

Case Study: Industrial Metal Repairs a Large Gouge to Refurbish a Drill Base Stand

A drill base stand undergoes refurbishment and repair with Industrial Metal used to seamlessly fill in a significant gouge caused by a previous owner’s misuse

Case Study: Repair of an 80mm Split to a Plastic Hose Supplying Water to a Pond

Landscaping work caused a 80mm longitudinal split to a buried plastic hose supplying water to a pond with a wider 300mm damage area successfully repaired by Sylmasta

Case Study: Reinforcement of Weakened 22 Degree Cast Iron Pipe Elbows

An elbow joint blow out alerted a water company that mains in their valve chamber were below spec, with Sylmasta reinforcing the pipes to prevent similar incidents happening in future

Case Study: Extending the Life of 20m Pipe Bridges Through Leak Repair & Reinforcement

Two 20m pipe bridges leaking sewage into a stream from numerous corroded joints undergo repair and reinforcement, extending their lifespan at a fraction of the cost of replacement

Case Study: Leak Repair & Encapsulation of a Steel & Iron Welded Pipe Joint

Sylmasta repair heavy damage and encapsulate a leaking welded joint between a 100mm cast iron pipe and a 50mm steel pipe in a church central heating system

Case Study: Badly Soldered Domestic Copper Pipe Leaking Joint Repair

Wrap & Seal repairs a domestic 22mm copper pipe leaking from a badly soldered joint which a property owner had long ignored, causing wooden floorboards underneath to rot away

Case Study: Chip Filler Repair to a Damaged £500 Designer Bar Stool Made of SMC

A homeowner quoted £220 to fix a chip in a £500 designer bar stool made of SMC instead made a cost-effective DIY filler repair using Sylmasta AB Epoxy Putty